Featured March 28, 2024

Coming Soon… Fillable PDF Forms

As many of you are aware, we have been working hard on developing new order …

Our gloves and hand products may be used to alleviate pain, restore functional movement and prevent future dysfunction. We are always working on innovating and developing our options for hand therapy so can have may options to choose from for your patients.

These garments provide unique thermal and protective properties and are especially recommended to provide support for amputations, delicate tissue and hypersensitive skin. They are sewn in a specialty thread to ensure they are durable and hard-wearing.

From a simple forearm sleeve to a full armsleeve with contractures, zips and linings, arm garments can be as basic or complex as needed to address the specific needs of the patient. On a standard armsleeve, the seam runs along the Ulnar side with edging along the distal end and silicon elastic is added to secure the proximal end.

Custom Finger stalls can be made in a fabric of your choice for compression and/or protection of individual fingers.

From the smallest glove for a one-year-old to a complex amputation garment, each order is manufactured with precision and care. We pay particular attention to ensuring we make our hand garments as accurately as possible and we enjoy the creativity and diversity that comes with working on different kinds of hands.

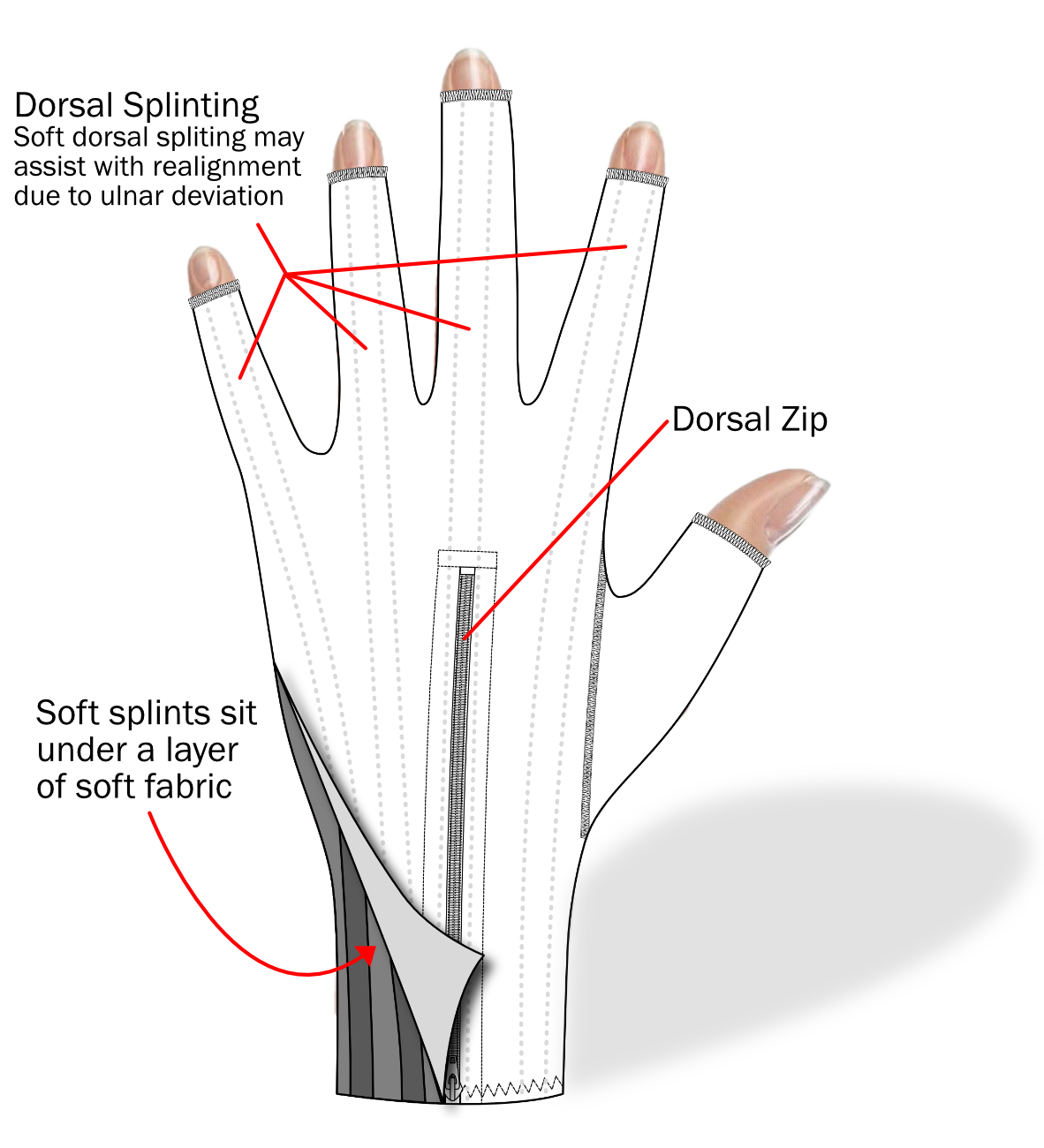

Soft Dorsal Splinting helps to maintain/encourage extension of fingers while allowing flexion when required. UPF Tex is used for the palmar aspect. 1mm Neoprene may be used instead on the palmar aspect for warmth and protection.

Featured March 28, 2024

As many of you are aware, we have been working hard on developing new order …

Featured February 14, 2024

For the past 26 years all new patients under the age of 15 have received …

Custom Made January 30, 2024

A solution to “sole of foot pre mature deterioration, and overcoming slippery occurrences” in lower …

Our friendly, experienced staff are available Monday to Friday from 8am – 4pm to answer any questions or queries.

Custom made garments are made to measure for individual patients while Ready to Fit is a dedicated range of pre-sized garments. If you are unsure about what kind of garment to order, we are happy to assist you to find the best option for your patient.

Custom Made

Complete the relevant forms for your chosen garment and email them to us at tsl@tslaustralia.com.au

Ready to Fit

Complete a Ready to Fit order form and email it to us at tsl@tslaustralia.com.au

We are happy to provide a quote if requested.

Alternatively, contact us to have a customer login created so you can browse our full range and place your orders online

Proper laundering will preserve the condition of your patients garments for as long as possible. A new garment will maintain optimal levels of pressure for 3-6 months with considered laundering and care. After this time frame it is recommended to replace the garment if necessary.

We advise you to wash garments daily with the following instructions to receive the maximum benefit from your compression garment:

Hand Wash

1. Ensure all zips and velcro are done up

2. Gentle hand wash in warm water using mild detergent

3. Rinse in cold water and gently wring out

4. Place in a towel and roll the garment in it to remove excess water

5. Place garment flat in shade to dry

Machine Wash – front loader only

1. Ensure all zips and velcro are done up

2. Place garment in a delicates bag or pillow slip

3. Wash on a gentle cycle with a mild detergent

4. Place garment flat in shade to dry

We have standard fabrics for all custom made garments based on garment type and diagnosis, however we also carry an extensive range of specialty fabrics that you may choose from if your patients have any specific needs. Choosing the correct fabric is integral to achieving the best outcomes with a compression garment so we offer a broad range of advanced compression and specialty fabrics to address a variety of concerns.

See our fabrics page for a detailed breakdown of our fabrics and colours.

A new garment will maintain optimal levels of pressure for 3-6 months with considered laundering and care. After this time frame it is recommended to replace the garment if necessary. On top of the laundering guidelines set out above, we also advise you to educate your patients on proper donning and doffing techniques and to regularly review garments for effectiveness, wear and tear.

Our care instructions come at the advice of leading compression garment researchers as well as from the guidelines set out by our fabric manufacturers. You can be comfortable in knowing we have taken every step to ensure our garments can maintain optimal levels of pressure for as long as possible.

All patients needing a compression or therapy garment manufactured by TSL need a written referral from a medical professional.